The combustion chamber of a waste incineration boiler is exposed to corrosive atmosphere where the temperatures can reach up to 1’400°C. It is obvious that the boiler walls must be protected accordingly to withstand high temperatures, the chemical attack and abrasion.

The heat transfer from the furnace to the steam boiler circuit is conducted through refractory linings in the furnace/first boiler pass and the other boiler passes. The lining is necessary to protect the steel walls, called membrane walls, from chemo-corrosive and abrasive attack by the hot and acidic combustion gases

In the furnace the temperatures are between 1’000°C and 1’800°C. The unprotected steel walls would be attacked by high temperature corrosion due to oxidation, abrasion, and corrosion. Accordingly, the walls must be protected by fireproof linings.

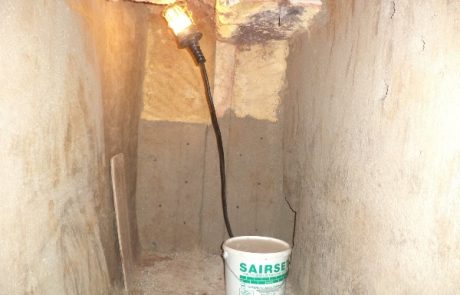

Some of the fire-resistant materials we use are:

- For high temperatures we use ceramic fiber plates for interior lining between sheet metal and insulation materials

- Die cast plastic masses with alumina

- Firebricks reinforced with Alumina

- High temperature fire cement

- For fastening we use fireproof or stainless steel fastenersin the form of scissors